FLUIDYNE INSTRUMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FLUIDYNE INSTRUMENTS P.LTD.

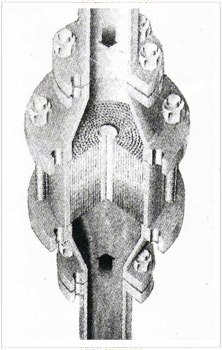

Flame Arrestors

Operation

Flame Arrestors, detonation flame arrestors, detonation arrestors, flame detonation arrestors stop the propagation of a flame by absorbing and dissipating heat through the large surface area of the bank sheets. Ignited vapour attempting to pass through the arrestor is forced through small passages within the bank assembly. Heat is absorbed, lowering the temperature of the gas below its ignition point and quenching the flame. Flame Arresters are typically used in the chemical, petrochemical and pharmaceutical industries on applications such as storage tank facilities, flare stacks, incineration systems, storage tank roofs or digester convertor to prevent the propagation of confined and unconfined delfagrations. Detonation flame Arresters additionally stop the high pressures and velocities that can result in detonations. Incase of ignition of vapours they burn harmlessly at the flame arrestor, preventing ignition of vapours in the tank and subsequent explosion.

Design Features

The main benefits of the 'Fuidyne Atmos®. detonation flame Arrestor, flame arrestors, detonation arrestors, flame detonation arrestors are derived from ifs unique element design. The large channel openings provide excellent pressure drop to flow and enhanced flow characteristics often resulting in reducing overall size and cost of both Flame arrestor and piping. In addition to this the less restrictive nature of the larger channel openings result in less clogging and easier cleaning - both important maintenance considerations. Finally the element enables higher operating pressures to be achieved. The 'Fluidyne Atmos®' Flame Arrestor after extensive research has been certified and type tested by FCRI, B.V. and other government agencies, and has also received the most stringent approval for Flame Arrestors, incorporating extended burn time performance, and have acceptance with B.P.C.L, I.O.C.L, H.P.C.L, L & T , REL , RIL & B.H.E.L., and many chemical, pharmaceutical , power industries and petrochemical industries.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.